Good preparation of certain details plays a crucial role in the successful transport of your machine. Scholpp has 12 tips for you to bear in mind before transport takes place. This will make the job easier for you and for us, putting everything in place to ensure the transport of your machine goes smoothly.

1. Clarify responsibilities

It is crucial that personnel interfaces and responsibilities are clearly defined to ensure good collaboration during the relocation of your machine. What is Scholpp’s role? And what tasks will you be taking care of? We will talk through these aspects and interfaces with you on site to ensure clarity in the division of tasks for both parties.

2. Check the transport route and loading/unloading point

You should be thinking about how to get the machine out of or into your hall at an early stage. Which opening could be used to bring the machine in or out? Would it be an option to lift the machine out through the roof? Take time to consider the route from the unloading point to the machine’s installation location as well. Are there ledges, slopes, or steep drops that could complicate our path to the installation location? The height of doors and lintels, any maneuvering space, building supports, the width of roads and gates, and the space for materials, equipment, and machines must also be sufficiently large.

It is also important to consider the load-bearing capacity of ground surfaces (e.g., asphalt or paving stones) both at the installation location and on the route. Asphalt surfaces in particular lose their load-bearing capacity at increased temperatures. Once all these aspects have been clarified and checked, we can talk through your thoughts, check the feasibility, and work through the overall concept together with you.

3. Make a note of the dimensions of the machine

Determine the size of your machine as exactly as possible. How heavy is it? How is the weight distributed? How big is it? Are there installation diagrams? Do you have securing devices for transport? Ideally, you will have lifting and transport instructions for your machines. This will include, for example, the mounting points for heavy-duty rollers, center of gravity for transport, and the requirements for loading or unloading using a crane or forklift truck. If you have pictures or layout diagrams of the machine, we would like to see them. We can then use all this information to work out how best to transport your machine.

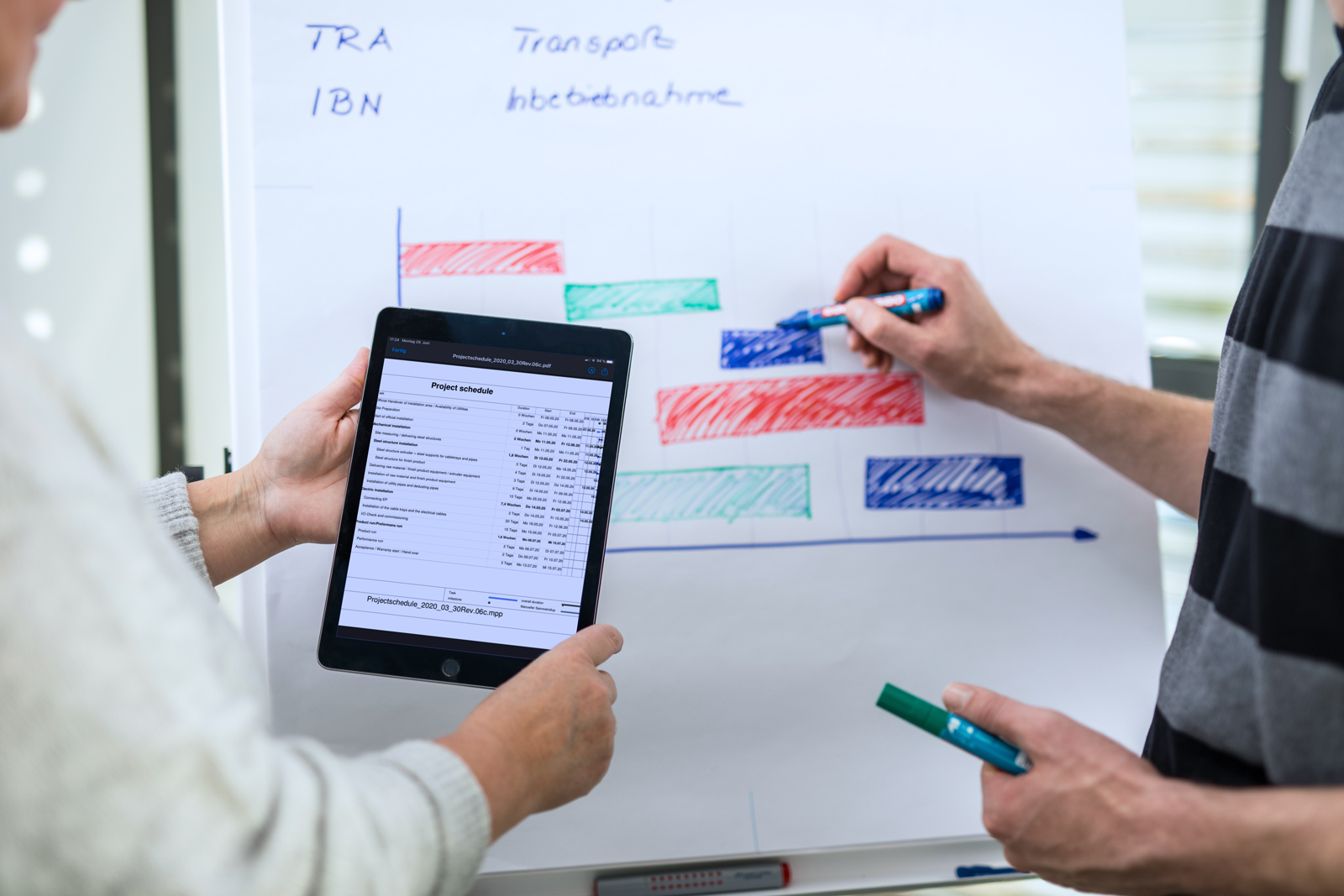

4. Establish the time frame for the move

Good scheduling is everything. A lot of aspects need to be taken into account for the timing of your machine transport. How much time is needed for the journey and installation? How much time do the various trades need, for example to lay foundations, coat floors, or provide media connections?

You also need to establish when, at the latest, you need the machine up and running at the new location – please bear in mind that Scholpp requires a number of weeks lead time to prepare all the work and the service providers. Administrative bodies and authorities often want to have a say in proceedings as well.

5. Check the load-bearing capacity of the floor

The floor at the new location must be able to withstand the load it will need to bear. This applies not only to the space where the machine will actually be installed, but also all the areas where Scholpp will need to position cranes and forklifts. The load-bearing capacity is reduced if, for example, there are other stories or basement levels beneath the surface, or cabling ducts are laid there. The material the floor is made of also plays a role here, of course. In many cases, Scholpp can find a technical solution for optimizing the load-bearing capacity of the floor at the site, for example using load-distribution panels, reinforcements, or prestressed girders with selective introduction of load.

6. Keep set-down points and maneuvering space clear

Transporting machinery requires space. Not just for the machine itself, but for its disassembled components and all the equipment used in the process. Therefore, you will need to keep sufficient floor space free for tool containers, forklifts, lifting platforms, in-plant crane, and plenty more. Your Scholpp project manager will let you know the exact equipment that will be used and its dimensions. We will be happy to calculate the required space for you.

7. Back up your machine data

Your machines contain digital control data that is essential for smooth operation. You should back up this machine and program data before transport, ideally making two copies (one local and possibly one in the cloud). This will ensure that the machine or plant can be recommissioned with no problems at the new location.

8. Disconnect the machine from media

Disconnect all media from your machine. This means that no operating media should be attached to your machine. For example, the machine should be disconnected from electricity, and liquid operating media should be pumped out. This applies especially to transport by truck, ship, or plane. It is essential that this is carried out before the machine can be disassembled and loaded.

9. Prepare operating current

When the equipment is installed on site by Scholpp, we will need electrical connections for large equipment in order to begin working. We may also require other infrastructure such as WLAN access or connection to a wastewater line. Our project manager will notify you of the types of connections we will require to start work. Please make sure that these connections are available on day X.

10. Register Scholpp personnel

We don’t only need our equipment to be available on your site, we also need our personnel. If your security arrangements require every individual who comes onto your site to be registered, please make sure you register our personnel in good time. This includes, for example, company ID, safety briefing, and other access authorizations.

11. Prepare for customs transactions

If a machine is to be transported by truck, train, or ship into a country outside of Europe, you need to prepare the customs papers in good time. This will ensure that the customs process in the destination country is handled relatively quickly and your machine will arrive at the destination on schedule. Use a customs agent who is familiar with the destination country.

12. Provide machine-specific lifting means

Has your machine previously been transported? Do you still have the machine-specific lifting means, transport cradles, or transport securing devices for securing moving parts? Now is the time to get these out of storage and check them for load-bearing capacity and function. These transport securing devices ensure that your machinery is not damaged during transport.

Leave A Comment