A

Air-cushion technology

A basic transport system used to move loads in two dimensions on air cushions. An air-cushion system consists of a number of elements. These are available in different sizes, with load capacities up to 60 tons. Compressed air takes on the “load-bearing” role in order to move heavy equipment and machinery into or within a hall. This “floating” method is safe and involves a reasonable workload, saving time and money.

Accident-prevention regulations

Accident-prevention regulations set out binding obligations with regard to occupational safety when using technical equipment. The purpose of these regulations is to prevent accidents by all possible means. Accident-prevention regulation BGV D6 applies to cranes.

C

Commissioning

Once a plant has been installed, it has to be put back into operation. This involves testing all mechanical and electrical components, as well as all of the machine’s functions, before the machine is put into operation.

D

Drafting winch

Drafting winches are used on both cable gantries and hydraulic lifting gantries. The winches and the associated trolleys or roller units can be used to move loads transversely on the endcarriages. They are driven either electrically or hydraulically.

E

Electric trolley

The electric trolley is a movable part of the crane that is responsible for changing the position of the hoisting cable. This is why these trolleys are also called crane trolleys. SCHOLPP uses electric trolleys on lifting gantries, allowing loads weighing up to 25 tons to be advanced and positioned electrically and with precision.

F

Floor load

The permissible load on the floor depends on the nature and condition of the surface. It is based on soil-pressure values. These are 25–30 N/cm² for unpaved ground, 50–60 N/cm² for paved ground, and 75–100 N/cm² for a road surface. The supporting area required depends on the supporting force required and provides the basis for the dimensions of foundation slabs. The pressure applied by the crane or transport vehicle must not exceed the permissible floor load. If it does, the floor will give way and the transport vehicle may tip over. Individual point loads also need to be taken into consideration.

G

Guide rope

The guide rope is used to guide loads safely during the lifting process. Care must be taken to ensure that a sufficient distance is maintained between the rigger and the load.

H

Heavy-duty beams

Heavy-duty beams–also known as endcarriages–are designed to meet highly specific structural requirements and are mounted on the lifting gantry. The load to be lifted is attached to the endcarriage. SCHOLPP has more than 100 specialist designs available to suit any lifting task, with spans of up to 22 meters and load capacities of up to several hundreds of tons.

Hook (also called a load hook)

Hooks are attached to ropes or chains and are important components for lifting gear.

Hook height

The hook height indicates the distance between the ground and the load hook.

Hydraulic sliding supports

Hydraulic sliding supports can be installed in the towers on the right and left sides of cable gantries. The gantry is raised up by means of an overhead crane, before the entire gantry is raised hydraulically into the travel range of the overhead crane. This maximizes the use of every centimeter on the construction site.

I

In-plant crane (also known as an industrial crane)

In-plant crane (also known as an industrial crane)

An in-plant or industrial crane is a compact crane that can travel with loads attached and does not require separate approval to go on the road. It is perfect for installing plants and machines, particularly in narrow halls and during ongoing production. It is available with electric and diesel drive options.

In-plant cart

In-plant carts are heavy-duty carts used for transporting loads of up to 250 tons within company premises. The carts have a hydraulic axle-compensation system for optimum load distribution and a lifting/lowering device for picking up and setting down loads.

Inspection service / inspection in accordance with UVV safety regulations

Every day, SCHOLPP uses up to 10,000 tools that require testing, such as lifting gear, ropes, chains, ladders, personal protective equipment, and hand-held electrical equipment. SCHOLPP’s own testing service inspects and repairs them on a regular basis in accordance with statutory regulations to make sure that the tools are always maintained and ready for use. This is the only way to keep the quality of the equipment at a consistently high level.

Installation supervisor

The installation supervisor is the construction-site manager and is responsible for processes on site. He or she coordinates the work on site and ensures that construction proceeds according to plan. He or she is authorized to issue instructions and therefore act as both the disciplinary and organizational supervisor for personnel on the construction site. The installation supervisor is the first point of contact for customers.

L

Leveling element

Leveling elements are located between the machine foundation and the machine. They ensure that the machine is precisely aligned and positioned to the hundredth of a millimeter.

Lift Link

A device that is slid over the heavy-duty beam before the lifting gantry is assembled. Loads are then attached to the lift links.

Lifting gantry

Lifting gantries can be used to handle loads weighing up to 1,200 tons, moving, rotating, and precisely positioning them in three dimensions. They are ideal for halls with tight spaces, varying floor heights and low ceilings.

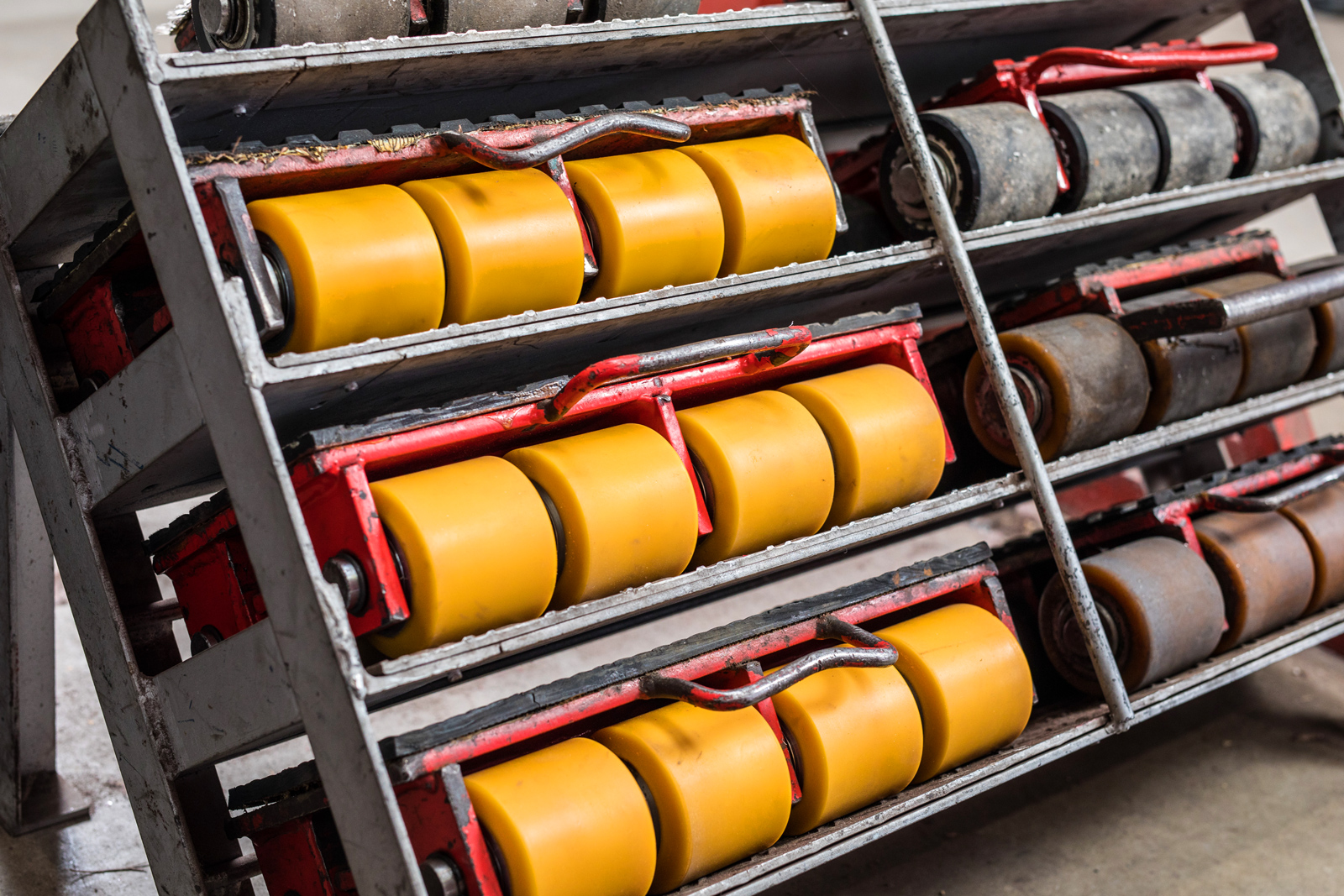

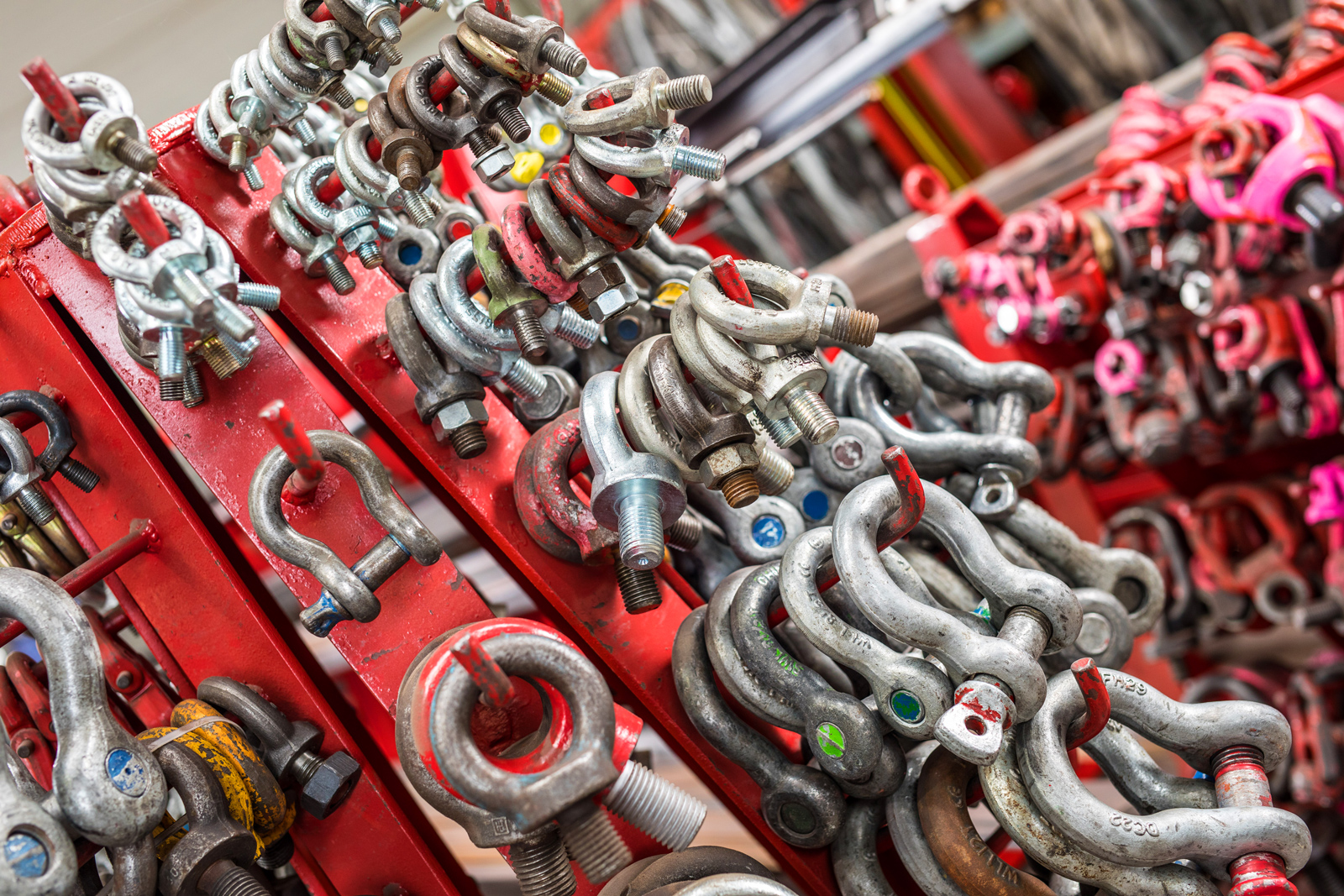

Lifting gear

Lifting gear

Lifting gear is load-bearing equipment placed between the load-bearing device (such as a crane) and the load to be lifted. This can include ropes, chains, slings, belts, and detachable parts, such as shackles or swivels. The maximum permissible load capacity is indicated on all lifting gear and must not be exceeded. Only components which meet the standards of DIN EN 818 are marked with the nominal size and grade.

Load

The load is the item to be lifted and moved by crane or gantry.

Load-bearing equipment

Load-bearing equipment is specific equipment that is designed to be force-locking or positive-locking. Examples of force-locking devices include sheet clamps, grabbers with recesses on the side or load-lifting magnets. Crane and coil hooks, on the other hand, are referred to as “positive locking”.

Load-capacity table

Crane and lifting-gear manufacturers produce load capacity tables for the respective crane and lifting gear for every conceivable boom combination. These depend, among other things, on factors such as boom type and length, boom inclination and ballast. A load-capacity table specifies exactly what loads can be lifted.

M

Machine-capability study (MCS)

A machine-capability study is a quick test that analyses the behavior of a machine with regard to specified characteristics and quality requirements. An MCS is most commonly performed when buying new machinery, but is also frequently done before commissioning on-site. Machines are inspected at regular intervals during production to ensure that they have the necessary capabilities and provide the required level of quality. A sample of workpieces determined according to statistical criteria (e.g., 50 items) is prepared under consistent conditions. The variables which play a critical role in how the part will function are then assessed. The 5 Ms—Manpower, Materials, Measurement methods, Machine temperature and production Method—must remain constant or vary only slightly throughout.

Machine foundation

The machines are placed on special foundations. In addition to being highly resilient and very precise, they can also absorb vibrations. Depending on the machine, a machine foundation can be up to 100 meters long.

Materials management

Materials management plays a key role in the installation process. This department is responsible for picking materials for construction sites and making them available on schedule. We also carry out repairs on our own equipment. Special designs for construction sites are manufactured in our own workshops and approved by experts when required.

Mechanical lifting gantry

The mechanical lifting gantry is a unique SCHOLPP innovation for the three-dimensional movement of loads in the narrowest of halls. The narrow support means that only 500 millimeters of space is required between the hall wall and the machine. The mechanical lifting gantry is mainly used in the installation of printing machines.

Moment

Moment or torque is calculated by multiplying force by the lever arm. For cranes, it is found in the terms “stability moment” and “tilting moment”. The stability moment is formed by the weights of those crane masses that press the crane onto the ground. The tilting moment is formed by the forces of the crane masses that would tend to make the crane tilt, as well as the load to be lifted.

A moment (formally represented by “M”) is calculated by multiplying force “F” acting perpendicularly on lever arm “h”: M=h∙F. Moment is measured in newton-meters (Nm): 1Nm=1kg∙m²/s². Tightening torque is the moment applied when a screw is tightened or fastened with a torque wrench.

N

Nivellierelement

Zwischen dem Maschinenfundament und der Maschine befinden sich Nivellierelemente, mit denen die Maschine im Hundertstel-Millimeter-Bereich exakt ausgerichtet und genau positioniert werden kann.

O

Oblique tension

Oblique tension places an unacceptable load on the components of the crane and must be avoided at all times. The lifting cable and the bottom block of the crane must always be exactly vertically above the load. When using a cable or a crane, oblique tension is only permissible in accordance with the load-capacity diagram.

P

Personal protective equipment (PPE)

Personal protective equipment is used to ensure the personal safety of employees on construction sites. PPE includes safety eyewear, safety shoes, hearing protection, hard hats, work clothes, and safety belts. These must be worn without fail when working at heights in excess of 3 meters to protect employees against falling.

Plant relocation

The relocation of an entire production assembly from one location to a new one is called plant relocation. This includes the dismantling, transport, installation, and commissioning of machinery and equipment.

R

ROBOT

The ROBOT is a remote-controlled, battery-operated transport system consisting of a simultaneously steerable and drivable chassis. The three-point support system makes it safe and easy to drive at the push of a button. The system is ready to go as soon as the built-in lithium-ion batteries are full. No external energy source is required. ROBOT chassis are used primarily in installation logistics and for heavy-duty internal transport. They can carry loads of up to 40 tons and can be extended with platforms and other equipment.

Radius

The radius denotes the distance along the boom that can be reached by the trolley. Together with the lifting height and the load, it is one of the most important factors when deciding on the size of the crane. The radius varies depending on the position of the boom. The smallest radius is next to the upright part of the crane; the largest at the far end of the boom. The permitted load capacity of the crane depends on the radius.

Reeving

If a load exceeds the tractive force of the winch on a crane or trolley, the cable must be reeved based on the principle of the pulley block to boost the lifting capacity.

Rigger

A rigger is a person whose work involves attaching loads. They prepare system to lift a heavy load, attach the load using suitable lifting equipment and are also responsible for setting it down safely.

S

Slinging of loads

Slinging a load means attaching the load with the aid of load-bearing equipment. A distinction is made between lifting gear and load-bearing equipment. The maximum permissible load capacity is indicated on all lifting gear.

Support

Supports are used to secure components and are primarily used when installing printing presses. The lifting gantries are usually set up on the second floor. As there is usually a basement area under the track, supports are used to dissipate the loads that arise. The supports used are either telescopic steel supports or wooden supports, also known as “Black Forest struts” here at SCHOLPP.

Swivel arm

A forklift truck can be converted into a crane by swapping the fork for a swivel arm. This makes it possible to lift loads from above and move them.

Support pressure

A considerable amount of force is applied to the ground through the supports. This pressure is known as support pressure. To ensure that the ground can withstand the pressure, the ground conditions must be checked in advance.

T

Track

A track is laid out under the lifting gantry so that the gantry can move back and forth across it. The rails of the track must be aligned parallel and fitted with an end stop. The track transfers the forces that occur into the floor of the hall. Sometimes the track has to be underlaid with hardwood ties to improve load distribution.

Theodolite

A theodolite is an optical instrument for measuring angles. It consists of a telescope, one vertical and one horizontal graduated circle and a number of spirit levels that are used to level the instrument. This precision instrument can be used to align machines on the machine foundation in two axes with a high level of accuracy.

Tool container

Tool or shipping containers are equipped with all the necessary tools, lifting gear and transport and slinging equipment required to carry out the work on the construction site in a professional manner. This means that there is always a fully equipped workshop available on site for minor repairs.